Click here to get this post in PDF

Food safety standards must always be maintained in manufacturing processes. The slightest lapse can result in foreign particles finding their way into the food and then subsequently into the consumers’ food consumed. Your clients’ health is of utmost importance, and hence there is nothing that you can leave to chances.

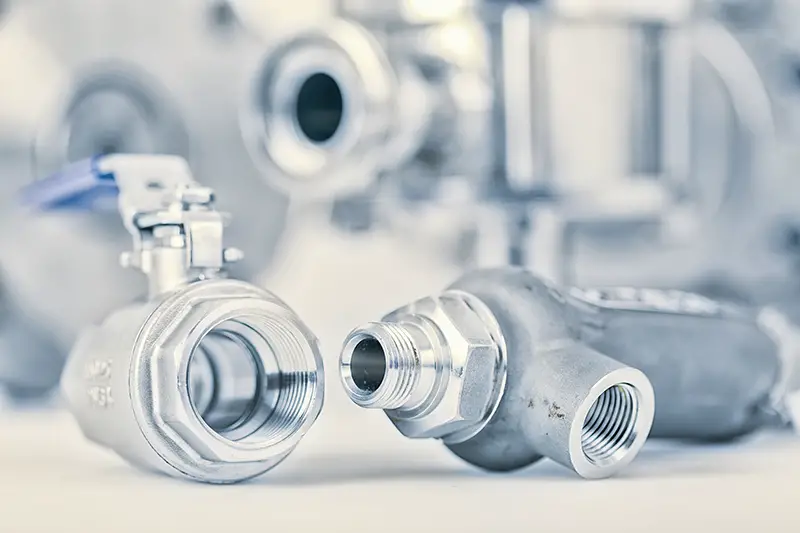

To ensure this, the manufacturing processes go through a lot of steps and procedures. Something that helps along the way is the numerous valves installed in the various machinery and industrial equipment. This article goes to explain the importance of stainless steel ball valves in the food industry.

Importance of ball valves

These have a vital role to play. Industrial ball valves are parts of all the machinery that is used to control the flow of various states of substances. They are pretty useful for regulating the fall of gaseous, liquids, and solid matters falling into multiple containers. There are various types of valves used to produce different requirements for different industrial machines. The most common variant type of ball which sees the maximum use is the industrial ball valves.

There is a special significance that valves play

These ball-shaped valves are positioned in the interiors of the pipes responsible for controlling the flow mechanism for the machinery. To suit specific requisites related to temperature, speed or pressure, there are many types of valves available. Chiefly, the fluid navigates the ball valve, and the liquid flow can be further controlled by the valve’s nature.

If need be, ball valves also show some resistance to the liquid’s flow inside while regulating it per second. It comes with manually operated handles, which can be switched on or off to get the needed flow in the pipelines. They are made up of very high quality and durable materials complete with flow regulation mechanisms that do not let corrosions happen for the longest time. The passageway is lined in the inner sides so that it does not limit the flow, while the mechanism keeps controlling the flow’s speed and pressure.

The Significance of having steel as the primary metal

Mainly, when it comes to industrial usage, brass and steel ball valves are put into use. However, due to many characteristics, stainless steel ball valve have become the frontrunner and continue to gain more attention. The longevity and corrosion-resisting properties make this metal ideal for long-term usage.

Also, these enjoy a higher pressure rating than their other counterparts, which goes on for 1000 PSI on a 1′ model on average. Also, it enjoys a greater scope to be used in many other applications because of its versatility.

Conclusion

Thus, now you must be well acquainted with the Significance of these little metallic parts. And if it is solid as steel, you can prevent any internal quality sub-standardization. They are the best bet if you want to go for absolutely sterile and clean processing.

You may also like: How To Prolong Business Machinery Life?

Image Source: Shutterstock.com